Additive & Dental Manufacturers - Room for Both in the Dental Space?

The dental market is in transition.

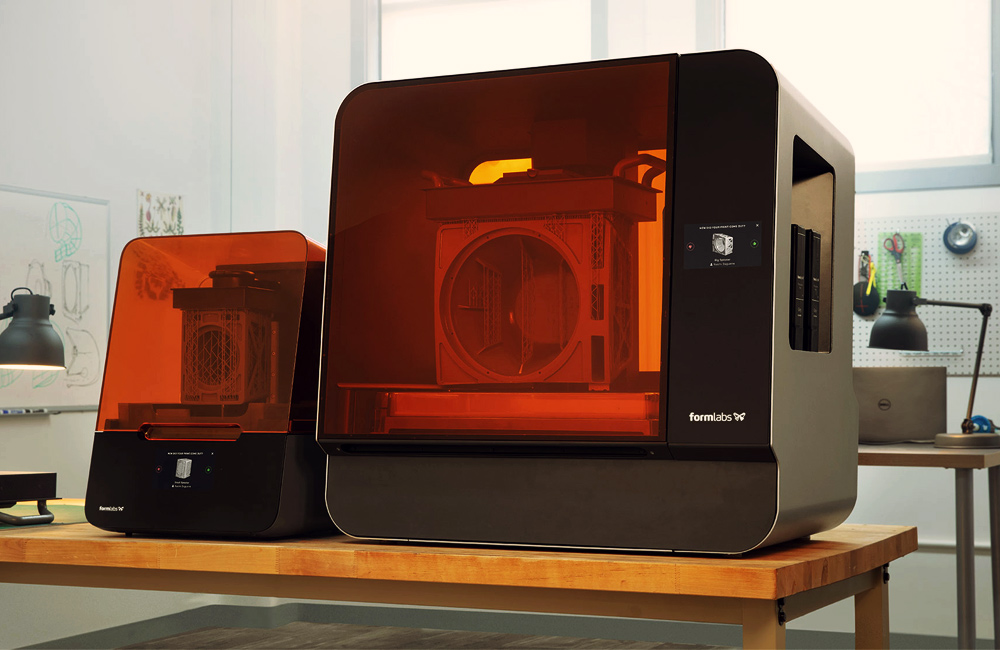

As we move progressively toward more digital solutions, the ability to 3d print implants and other dental products and devices has become more and more important.

But 3d printing anything is a complicated business, and 3d printing for the dental industry is significantly more complicated than for traditional industrial applications. Thus far, we’ve yet to see one pure dental 3d printing business who has both the medical and industrial know-how to completely corner the market.

This means the market has been left with two sides, both vying for customer attention. On one side, the industrial additive manufacturers – those with significant experience in the 3d printing arena who are looking to crack the dental sector – and dental manufacturers who recognise the need for 3d printing in the dental surgery and as such have been investing heavily in their own 3d printed technology.

As someone who works across the entirety of the dental space, I’m in the somewhat luxurious position of having access to experts from both sides of the 3d printed fence. So, I took the time to speak with industry experts from dental manufacturers Kulzer and Ivoclar Vivadent as well as a company with more traditional CAD/CAM engineering expertise, albeit with a focus on the dental space, INFINIDENT Solutions.

Speaking to each individually, I covered a range of topics and ultimately tried to see what the future holds for dental 3D printing.

The Differences

First, I felt that it was important to establish the key differences, in the eyes of the companies themselves, between traditional dental equipment manufacturers and 3d printing companies.

I spoke with Thomas Beier, Product Manager for leading international dental company Ivoclar Vivadent who felt that it was the specialist knowledge being brought to the table that makes the difference for expert dental companies. He said that “to be successful in the dental market, a company has to understand the special requirements of the dental market and the differences to other markets” and it’s true – the regulations surrounding the dental space are stringent.

According to a contact of mine from CAD/CAM specialist INFINIDENT Solutions, providing an exceptional service to the customer with a highly specialised dental background is mandatory in the dental market as well as having a good understanding of CAD/CAM technologies. His belief was that specialist CAD/CAM knowledge would help with service delivery, as dental companies simply adding 3d printed products to their traditional portfolio may struggle when it comes to delivery. It is not a simple process to integrate the technology into the daily work flow.

“You have to speak the language, you need experience on the material and technology side. Plus, you have to fulfil the customer expectations.”

Dr Sascha Cramer Von Clausbruch CTO of Kulzer Dental believes that a benefit of having specialist expertise in the dental field means that customisable, highly complex 3d printed solutions can be manufactured. He said that their specialist knowledge enables Kulzer to “offer products with USP’s and added values which separate [them] from competitor products”.

So it’s clear that both sides have their own strengths and expertise, but is the market big enough for both?

Can they co-exist?

I asked all 3 experts if they could see a future where each have their own place in the market and interestingly, all 3 agreed that expertise from both fields was invaluable and necessary for the longevity and success of the sector.

Thomas Beier put it succinctly, said “I think dental additive manufacturing will always be an adjustment from the regular additive market. Each will have its own place, especially because the ‘regular [3d printed additive] market’ will never fit all the requirements of the dental market.”

So, it’s not a matter of asking the question of if these two markets can coexist because, at the moment at least, one cannot exist without the other. Up until now, no pure-play 3d printed dental specialist has established themselves as a leading brand in the space. To access this lucrative new market, dental companies have had to quickly learn 3d printing and 3d printing businesses have had to get to grips with the complexities and regulations that come with working in this area.

The Future

Everyone I spoke with was in agreement that this technology has a significant part to play in the future of dental technology and treatment. Dr Cramer said that 3d printing “will play a significant role in the future, especially for resin-based dental materials respective indications”.

When asked if he thought the technology had a big part to play in the future, Thomas Beier said they absolutely will, particularly with polymer appliances which can be manufactured much faster using 3d printing methods.

On the other side of the coin, my contact from INFINIDENT agreed that the dental market was here to stay for additive manufacturers, mentioning that part of their production cycles are based on additive technologies already.

“The first dental company which provides printer, materials, a validated process and support for dental requirements, will have a big competitive advantage.” – Thomas Beier

So if that’s the case – is there a gap in the market for a specifically tailored, one-stop shop which blends the best of both worlds? Noone’s cracked that magic formula just yet, but that’s what makes this such an exciting market to be working in: everyone knows that the future will be 3d printed, just nobody is quite sure what form it will take.

Recommended.

A Booming Market Is Inspiring Innovation for 3D Printing in Dental.

3D printing in dental is a booming market. There’s an abundance of exciting technologies coming from companies big and small, from all over the world.

The Unknown Unknowns of M&A

Even if you’ve been through the process, you may not be aware of exactly what goes into M&A deals. Today, we’ve tried to look into that in a little more detail with Transaction Liability Team Leader Grant Hollis from CFC Underwriting.

The 4 Day Week

As businesses prioritise the wellbeing of their employees, the concept of working a 4 day week is shifting from distant pipedream to reality for a range of organisations around the world.

Additive & Dental Manufacturers - Room for Both in the Dental Space?

The dental market is in transition. As we move progressively toward more digital solutions, the ability to 3d print implants and other dental products and devices has become more and more important.

Comments.