3D Printed Implants The Future of Spine?

In my position, as a spinal specialist, I work across the entirety of the spinal market, which means that I have a uniquely objective view of the whole market. Over the past couple of years, one of the most interesting technological advances I’ve seen emerge has been within 3D printing or, more specifically, 3D printed spinal implants.

3D printed technology is nothing new, but the innovation I’m coming across in the spinal implant space right now has led me to ask the question, is this technology the future of the entire spinal implant market?

Why are people interested?

If you’ll excuse the pun, any surgical procedure is carried out on a knife edge. Whatever operation is taking place, surgeons are operating with the most miniscule margins for error. For surgeons working in spine with so many different parts, this is amplified even further.

So, any technology that can increase the chances of success, or decrease those margins for error understandably causes a big stir, which is where 3D printed implants come in. The way in which they are manufactured means that, whether they’re completely bespoke or part of a range of ‘off the shelf’ implants, they’re more likely to reduce the chances of implants not fitting correctly and repeat surgeries.

As well as reducing the physical pain that comes with repeated surgical procedures, 3D-printed implants will help with a patient’s emotional well-being and understanding of their procedure. Thanks to the technology, surgeons can now show a patient a model of their spine and explain how a surgery will go with a model, as opposed to a complex MRI scan.

It’s been well documented that mental trauma and anxiety can hinder recovery within patients, or have them more on edge when entering theatre – being better informed and therefore better prepared, means that patients are much less likely to feel as though they have no control or clue what is happening to them when under anaesthetic.

Who’s involved?

The benefits are clear then. Improved chances of success for surgeons and more confidence for patients. Unsurprisingly, there are a whole host of companies getting into the 3D printed space.

Emerging Implant Technologies (EIT) are one such company, and their mantra of ‘get it right first time’ is something surgeons can clearly get on board with. They manufacture a full line of ‘off the shelf’ implants, so not individual, but the cellular titanium used means that the chances of a successful surgery are greatly increased.

57% YoY growth is impressive for any business and it’s a statistic that 4WEB Medical, a US-based competitor of EIT, can boast for 2017. They’ve also reported an 84% increase in surgeon usage for their range of ‘off the shelf’ products – representative of an exciting marketplace. We’re also seeing even more companies entering, with K2M and Si Bone two more exciting businesses creating some innovative products.

4WEB’s Cervical Spine Truss System

When it comes to truly individual and personalised implants then Medicrea are the pioneers. Each one of their individually personalised implants is unique and bespoke to the patient. Implants and technologies like theirs represent a new era of truly individualised precision medicine.

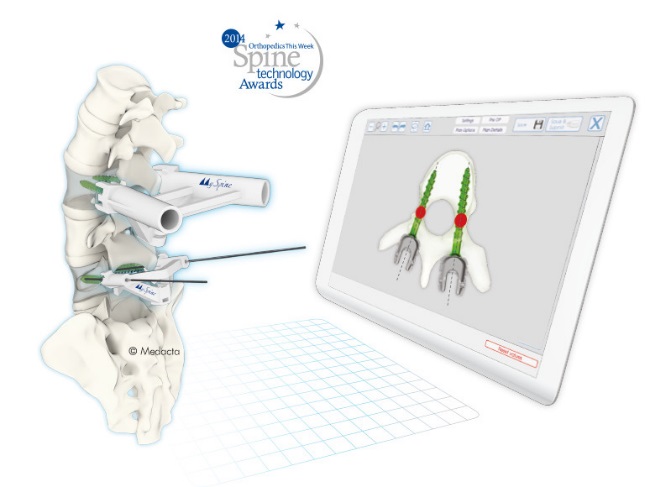

Medacta also have their own 3D printed MySpine range – an example of a major international business adopting 3D printed spinal implants as an additional product line.

The Medacta MySpine system

What are the problems?

Implants like those produced by Medicrea or Medacta are at their most useful when a patient is experiencing a particularly rare or individual problem. A congenital deformity, severe spinal degeneration or destruction of the spine from a tumour are all applications when their implants have the most benefits.

For other, more urgent, procedures even where a personalised implant would be preferable, the timescales involved in designing, modelling and creating an implant just don’t work. The current process can take days, which is far too long in A&E or ER where time can be so critical to success.

In addition to their slow production process, they can be costly. A 3D printed implant can cost anywhere between $300 - $1000 more than a traditional commoditised product. With the number of spinal operations happening every day in hospitals around the world, this cost can very quickly run into millions of dollars.

There is a counter argument to this though, that increased success rates mean that the amount of repeat procedures would decrease – potentially offsetting the cost by avoiding the far more expensive second procedure.

What does the future hold?

In my opinion, the future of spinal implants inevitably lies with 3D printing technology, but the reservations I’ve already mentioned will need to be addressed before we see widespread adoption and a 3D printer in every hospital.

Competition will help. As demand grows, we’re already seeing more and more businesses emerge every year, and as competition grows, I’m sure that we’ll see the innovation needed in both the software and CAD technology to bring production times down from days to hours or even minutes.

I’m also confident that we’ll see a reduction in some of the regulatory hurdles that come with creating individual implants – something that organisations like the FDA will be working towards in order to allow a more competitive market.

Recommended.

Innovative Spine & Orthopedic Implant Technologies to Watch.

Orthopedics isn’t necessarily a market commended for its digital innovation, but these five companies are proving differently with their latest product launches. Click to read more.

What Innovations Could Shape the Future of Orthopaedics?

To achieve personalised care in orthopaedics, we need advances in AI, surgical robotics, augmented reality (AR) and more! But where will this innovation come from? Click to find out.

3 Technologies Revolutionising Spinal Surgery.

New innovations have continued to advance surgery – especially within the spinal space. I wanted to highlight the revolutionary technology that is driving this change and shaping the future of the space.

How to Take Your Medical Device to Market.

In this episode, I'm joined by Steven Haken and Deborah Rizzi from market access and reimbursement specialists Odelle Technology to discuss how to take a medical device to market.

Comments.