What Innovations Could Shape the Future of Orthopaedics?

Everyone is different.

The same goes for orthopaedics patients. We differ in size, the condition of our bones/tissues and the necessities of our joint replacements.

This means joint replacement surgery is never a one-size-fits-all proposition and more personalised patient pathways often lead to better results. In recent years, we’ve seen the industry take a step in this direction and personalised care is sure to be a part of orthopaedics’ future.

But to achieve this, advances in AI, surgical robotics, augmented reality (AR) and other technologies are crucial. So, how much are these innovations helping right now?

AR has been in the surgical suite for years.

Even before the pandemic, this technology was being used to improve accuracy, efficiency and provide real-time patient data in the operating room (OR). However, since COVID-19 we’ve seen an uptake in its adoption.

AR provides its users with computer-generated perceptual information to support them in surgical procedures. For example, this information could be instructions or 3D imaging that’s added to the user's view via mobile devices and headsets.

In January, Jonathan Vigdorchik, a surgeon at the Hospital for Special Surgery (HSS) performed the US’ first knee replacement surgeries supported by the technology. For this, he relied on Medacta International's NextAR augmented-reality platform and a pair of AR glasses developed by Vuzix Corp.

Before the procedure, Vigdorchik performed computer tomography knee scans on his patients and loaded them into the NextAR platform. The platform then developed 3D models of the patients' knees to support his preoperative planning.

In the procedure, the AR glasses enabled Vigdorchik to see the patient and a digital display of the patient’s leg with a 3D model superimposed to show a diagram of each planned cut. If he cut correctly, the line on the model turned green. If incorrect, the line turned red.

These operations were a major milestone for orthopaedics, with AR set to play a vital role in the future of the surgical space. However, this is not the only technology that is helping procedures become more accurate and personalised.

For example, Orthosensor’s Verasense (now part of Stryker’s offering) allows surgeons to quantify ligament balance and customise implant position during primary and revision total knee arthroplasty (TKA). This is a major advance on traditional methods which relied upon surgeons to use their feel and judgment to determine whether the knee is balanced during the operation.

But now, using the Verasense – which is a disposable, intelligent device – surgeons are provided with real-time data wirelessly which they can view via an intra-operative monitor, the LinkStation MINI, in the OR.

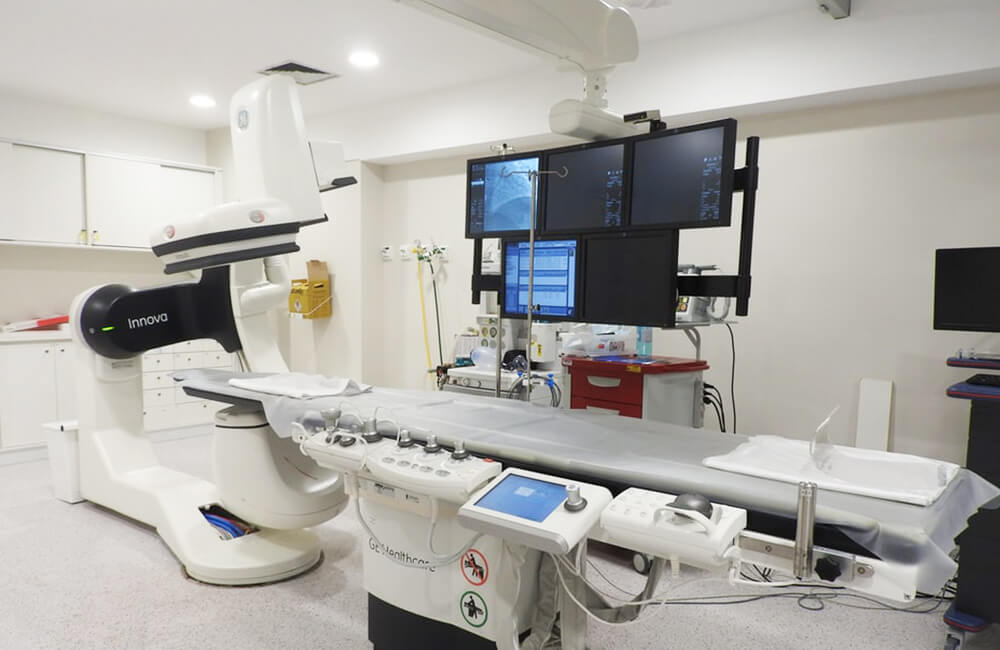

Strykers’ offering does not stop there. The med-tech giant is also building out a product offering around its Mako robotic arm, which has been developed for joint replacement surgeries.

The Mako’s guidance allows for a more accurate and better-aligned joint replacement. The device also supports a more personalised treatment, with the surgeon’s planning and operation supported by a 3D virtual model of a patient’s knee’s unique anatomy (created from a CT scan).

Strykers’ US compatriot, Zimmer Biomet, is also advancing surgical robotics offering. This April, the company received FDA clearance for its Rosa Partial Knee system which can be used for partial and total knee surgeries. This is the latest addition of Zimmer Biomet's suite of integrated digital and robotic technologies, ZBEdge.

The ROSA Knee System assists surgeons with Total Knee Arthroplasty (TKA). The system’s features help with the bone resections, as well as assessing the state of the soft tissues to facilitate implant positioning intraoperatively to make surgery accurate and safe.

This year, Zimmer plans to launch the Persona-IQ too. This is a next-gen version of its successful, personalised Persona Revision knee implants that will incorporate a CHIRP sensor. These sensors are an innovation of Canary Medical and are able to self-report on function, diagnostic information, patient activity, side effects and treatment failure for up to 20 years.

This data and monitoring leads to better patient outcomes and helps surgeons get a better idea of patient compliance. It also acts as an early warning system for issues and helps patients take control of their own health and recovery.

While these devices are incredibly impressive, it’s also important to appreciate how 3D printing has been revolutionising orthopaedic implants in recent years.

With this technology, we’ve found a way to create custom design orthopaedic implants that are unique to a single patient’s anatomy. This provides benefits including less time in surgery, a faster recovery, a greater range of motion and longer-lasting implants.

Lima Corporate, a global medical device company headquartered in Italy, has long been at the forefront of 3D printing innovations in orthopaedics. Now the company is partnering with HHS in a way that no-one has ever done before.

Together, LimaCorporate and HSS are founding the first design and additive manufacturing 3D printing facility for custom complex implants on a hospital campus. This collaboration will increase the availability and speed of personalised orthopaedic care for patients with complex conditions in the US.

All these innovations (AR, sensors, surgical robotics, 3D-printed implants, smart implants), have created a patient pathway that can be heavily personalised. However, to further personalise the patient pathway, digital platforms have been introduced to connect patients and surgeons throughout their journey.

Exactech, which was founded by an orthopaedic surgeon called Bill Petty, is helping surgeons and patients’ partner via its AI-powered platform, Active Intelligence.

The platform’s digital communication tools streamline the way surgeons interact with patients and collaborate with peers on surgical challenges. Its software and planning applications also use machine learning to visualise individual patient outcomes and map surgical plans too.

This is a growing space with Smith & Nephew also providing a leading platform, Real Intelligence. But instead of using AI, Real Intelligence harnesses the power of human insight and experience to create care pathways. It’ll be fascinating to see how these platforms develop as the technologies around them continue to advance too.

Thanks to these platforms and technologies, surgeons and patients are partnering in a way that they’ve never done before. By working together, they’re creating more personalised patient pathways that are leading to more accurate treatments and better care.

As we continue to move away from a one-size-fits-all model, it’s important that we continue to celebrate the people and companies within our industry that are pushing boundaries and innovating. Personalised care is the future for orthopaedics and advancing the technologies I’ve mentioned in this article is key.

If you know of a company in the space that’s doing something truly innovative, I’d love to hear about it. Please feel free to give me an email at Lloyd.Hines@medical-cm.com.

For more about me and what I do in orthopaedics, check out my profile page.

Recommended.

Innovative Spine & Orthopedic Implant Technologies to Watch.

Orthopedics isn’t necessarily a market commended for its digital innovation, but these five companies are proving differently with their latest product launches. Click to read more.

What Innovations Could Shape the Future of Orthopaedics?

To achieve personalised care in orthopaedics, we need advances in AI, surgical robotics, augmented reality (AR) and more! But where will this innovation come from? Click to find out.

3 Technologies Revolutionising Spinal Surgery.

New innovations have continued to advance surgery – especially within the spinal space. I wanted to highlight the revolutionary technology that is driving this change and shaping the future of the space.

How to Take Your Medical Device to Market.

In this episode, I'm joined by Steven Haken and Deborah Rizzi from market access and reimbursement specialists Odelle Technology to discuss how to take a medical device to market.

Comments.