Is Bioprinting the Most Important Technology of Our Lifetime?

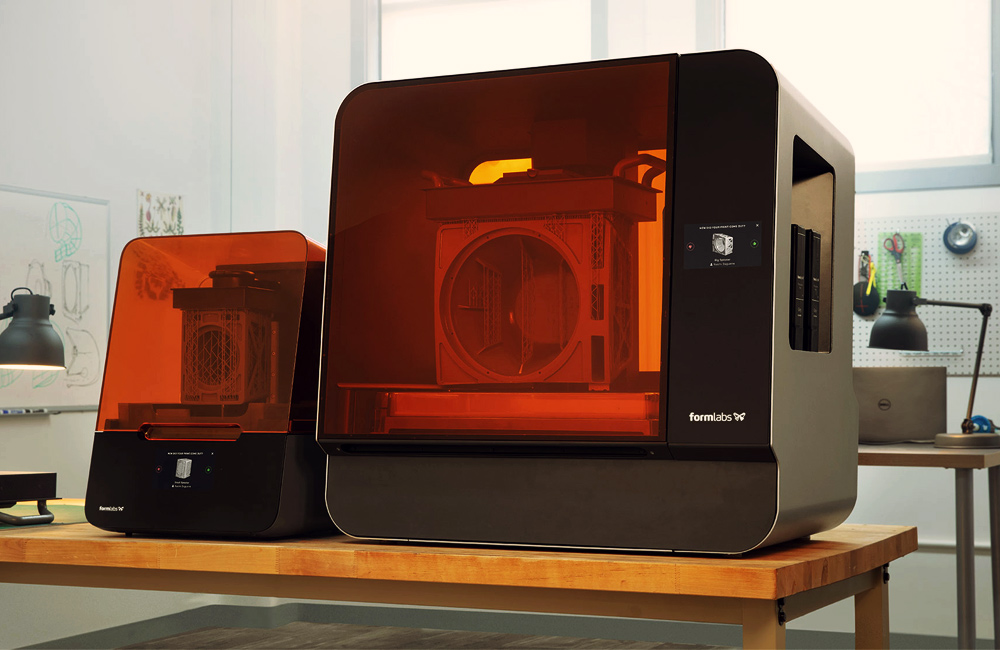

The industry of additive manufacturing, commonly known as 3D Printing, is by no means a brand new and ground-breaking concept. In fact, additive manufacturing is said to have emerged during the 80’s. But it’s come a long way in 30 years.

Additive manufacturing is a process that’s improving the medical industry across the board in dental, orthopaedics, spine and countless other areas. However, bioprinting is by far the most exciting thing to have emerged from this space in the last decade.

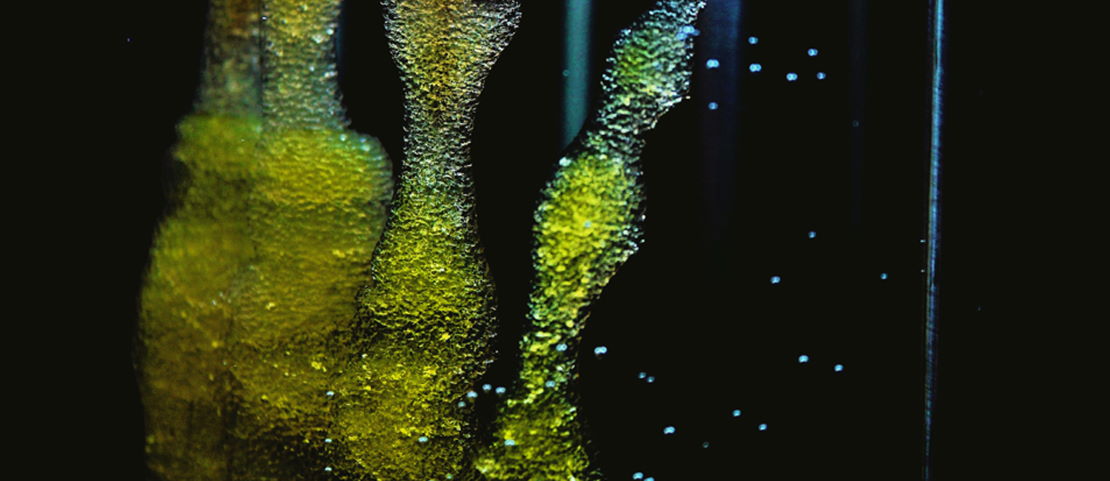

Bioprinting uses human tissue in the additive process to create complex 3D structures that can function as organs or anatomical structures.

There’s no doubt about its potential, which is reflected by the serious investment we’ve seen in the technology across the medical industry. Many leading multinationals have teamed-up with companies specializing in this technology, suggesting that this is the way that healthcare is heading. Some examples include Stryker’s partnership with GE Additive (formerly Concept Laser and Arcam), Johnson & Johnson with Organovo and Straumann’s increased stakes in Rapid Shape.

Thanks to the strains of both a growing and ageing population on health services, demands for innovative solutions like bioprinting are incredibly desirable. Improved healthcare has led to a larger and older population which has consequently led to an increase in patients with chronic illnesses. This increase has sky-rocketed the demand for organ transplants worldwide. Despite the rising population, a similar increase in organ donors has been non-existent. That’s where bioprinitng comes in.

Bioprinting has the potential to offer quicker and cheaper production of individually customised prosthesis to combat this issue. If the ongoing research into bioprinting is successful, such solutions would be highly attractive to both public and private healthcare providers.

There’s also a place for bioprinting in pharmaceuticals, with it improving the drug-testing process. If tissue can be printed to accurately mimic human tissue, this would help drug companies test products quicker, using less resources and to higher levels of accuracy. This would make sure that drugs coming onto the market were far safer, while also bringing a financial benefit to this multi-trillion-dollar industry.

The technology is exciting, but we’re not quite there yet – especially in prothesis. Due to difficulties like the complexity to recreate a structured network of blood vessels that could provide tissue with enough oxygen to survive, it’s not possible to print a full-size organ made from human tissue. However, some scientists suggest that we won’t be waiting long and predict that a printed 3D heart is less than a decade away.

It all sounds too good to be true and sadly, that’s correct. There are some major complications that we’ll need to take into consideration as this technology advances.

Although it’s not quite the same as human cloning, the ethics behind the artificial production of human cells will need to be discussed. Therefore, it may be some time before the applications of this technology are widely accepted by patients and drug users.

Liability will also be a controversial matter. When a printed organ is successfully transplanted to a patient, what happens if something goes wrong? What if it fails post-surgery and a patient’s health becomes at risk? Who is liable for this – the manufacturer or the hospital?

These are definitely hurdles to overcome, but let’s not take away from the life-changing potential that bioprinting offers. It’ll be fascinating to see what happens next in this space, with more investment and innovation certain to follow.

Recommended.

A Booming Market Is Inspiring Innovation for 3D Printing in Dental.

3D printing in dental is a booming market. There’s an abundance of exciting technologies coming from companies big and small, from all over the world.

The Unknown Unknowns of M&A

Even if you’ve been through the process, you may not be aware of exactly what goes into M&A deals. Today, we’ve tried to look into that in a little more detail with Transaction Liability Team Leader Grant Hollis from CFC Underwriting.

The 4 Day Week

As businesses prioritise the wellbeing of their employees, the concept of working a 4 day week is shifting from distant pipedream to reality for a range of organisations around the world.

Additive & Dental Manufacturers - Room for Both in the Dental Space?

The dental market is in transition. As we move progressively toward more digital solutions, the ability to 3d print implants and other dental products and devices has become more and more important.

Comments.